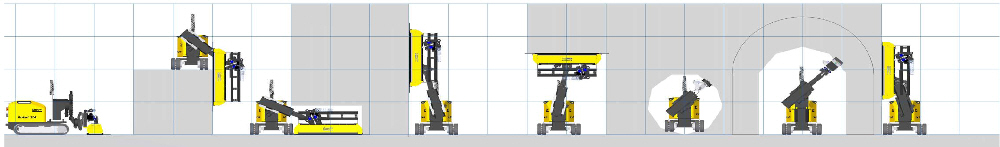

Robotic Demolition and Surface Preparation Equipment

The Conjet Robot 324 is a small water jetting machine which revolutionises the hydro-demolition and surface preparation industry with its compact design and flexibility.

The small Robot 324 opens up new areas for mechanising concrete removal.

Using this method gives superior bonding due to the absence of micro cracks and replaces inefficient hand lancing and jack hammering and other percussive methods. The Robot 324, weighing just over one metric ton, has been developed to work in confined spaces and areas inaccessible to larger hydro-demolition machines. The robot passes easily through less than a 0.9 m (3ft) wide opening. The exceptional manoeuvrability of Robot 324 makes it the perfect machine for operations in any confined areas like small tunnels, tubes and inside concrete box girders.

Due to its low weight which is evenly distributed via the tracks, the Robot 324 can be operated safely and easily on platforms and scaffolding. The Robot 324 is also the ideal tool for numerous industrial cleaning and surface preparation contracts.

The various blast head configurations make this an ideal tool for removing concrete latencies, scabbling, epoxy coating removal, mastic asphalt removal etc.

Our contracts web page gives fuller details of surface preparation within a pipeline using the Robot 324.

Nalta

The Conjet Jetframe 101 NALTA has been designed to replace hand lances for a large number of hydrodemolition applications,increasing productivity and improving safety for operators.

The compact and lightweight Jetframe 101 NALTA is supplied with high pressure water from a standard hand lance pump and can operate on flat as well as curved surfaces with a radius as small as 400 mm. It is mainly used for the hydrodemolition of concrete, but is also suitable for other applications, such as surface preparation

and descaling of steel. The Jetframe system NALTA consists of a feed beam with an oscillating lance, hydraulic unit and a remote control box. The oscillating lance, fixed to the cradle, travels along the 1m long feed beam, which can also be extended with two extra sections to a maximum length of 3m. The cradle moves, oscillating the lance between two manually set turning points on the feed beam. At each turning point, the lance angle of attack inverts. This function is mechanically automated which enables the unit to operate under water. The Conjet research team has come up with a

patented solution which allows four hydraulic hoses to control all functions of Jetframe 101 NALTA, including cradle movement, lance oscillation and angle as well as feed beam indexing step units.The step units can automatically move the feed beam on scaffold tubes formed to a minimum diameter of 800 mm By using support legs the feed beam can be mounted behind the scaffold tubes to provide unrestricted access to the cutting area.

© NET Waterjet, Unit 1, Mid Friarton, King James Business Park, Perth, PH2 8EL